The Process of Creating Wood Laminate Flooring: A Step-by-Step Guide

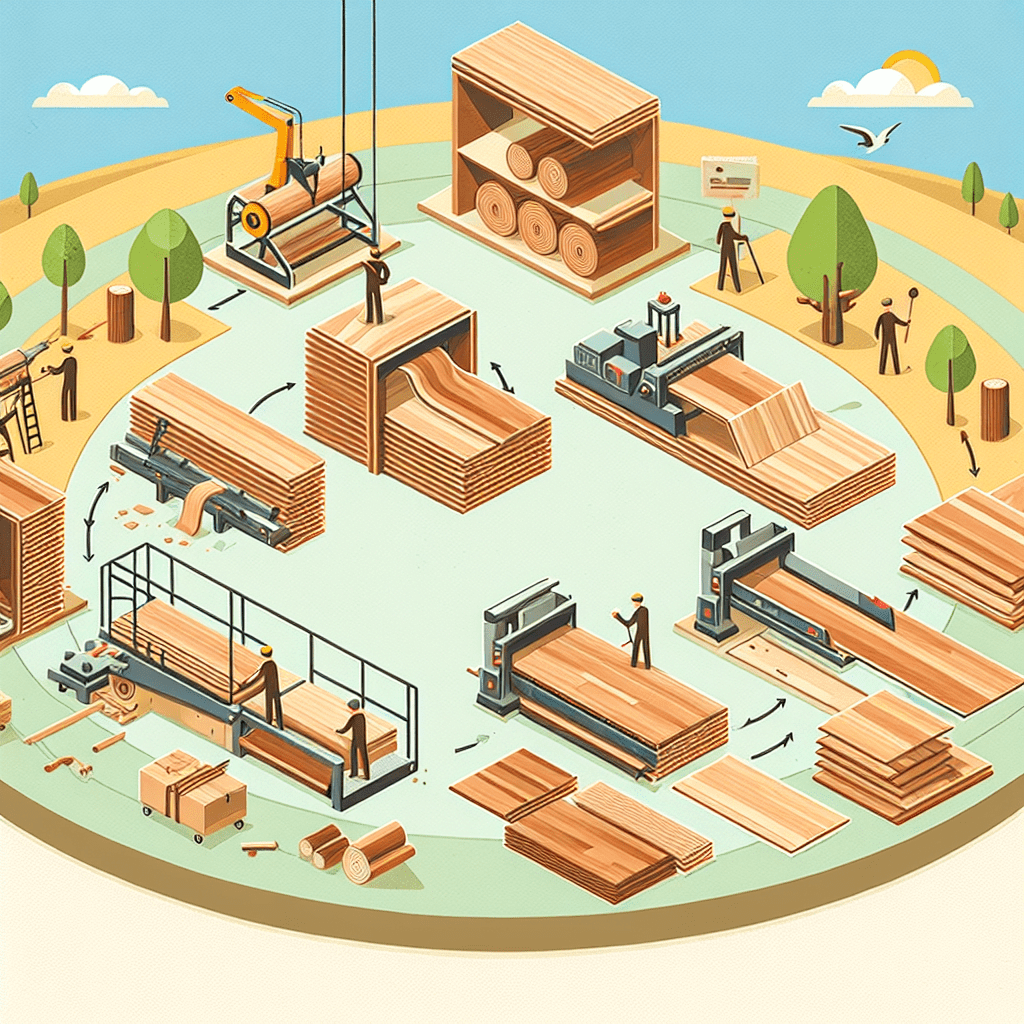

Wood laminate flooring has become a popular choice for homeowners and businesses alike due to its durability, affordability, and aesthetic appeal. But have you ever wondered how this type of flooring is made? In this article, we will take a closer look at the process of creating wood laminate flooring, from start to finish.

The first step in creating wood laminate flooring is selecting the materials. The top layer, or the “laminate,” is made from a high-quality image of wood grain that is printed onto a thin layer of paper. This paper is then treated with a melamine resin, which gives it its durability and resistance to scratches and stains. The core layer is typically made from high-density fiberboard (HDF) or medium-density fiberboard (MDF), which is a composite material made from wood fibers and resin. The bottom layer, or the “backer,” is made from a moisture-resistant material such as plastic or paper.

Once the materials are selected, the next step is to create the laminate layer. This is done by printing the wood grain image onto the paper using a high-resolution printer. The paper is then treated with the melamine resin and cured under high heat and pressure. This process creates a strong and durable top layer that is resistant to wear and tear.

After the laminate layer is created, it is time to create the core layer. The wood fibers and resin are mixed together and then pressed into large sheets. These sheets are then cut into the desired size and shape for the flooring planks. The thickness of the core layer can vary depending on the manufacturer and the desired level of durability.

Once the core layer is ready, it is time to assemble the flooring planks. The laminate layer is glued onto the core layer, and the backer layer is added to the bottom. The planks are then pressed together under high heat and pressure, which creates a strong bond between the layers. This process is known as lamination and is where the term “laminate flooring” comes from.

After the planks are laminated, they are cut into the desired size and shape. The edges are then treated with a special sealant to prevent moisture from seeping in between the layers. This also helps to create a smooth and seamless appearance when the planks are installed.

The final step in the process is to add the finishing touches. The planks are sanded to create a smooth surface and then treated with a protective coating to enhance their durability and resistance to scratches and stains. The planks are then inspected for quality control before being packaged and shipped to retailers.

It is important to note that the process of creating wood laminate flooring may vary slightly depending on the manufacturer and the specific type of flooring being produced. However, the overall steps remain the same.

In conclusion, wood laminate flooring is made by combining a laminate layer, core layer, and backer layer under high heat and pressure. This process creates a strong and durable flooring option that is resistant to wear and tear. With its affordability and aesthetic appeal, it is no wonder that wood laminate flooring has become a popular choice for many homeowners and businesses. So the next time you walk on your wood laminate flooring, you can appreciate the intricate process that went into creating it.

From Tree to Floor: The Journey of Wood Laminate Flooring

Wood laminate flooring has become a popular choice for homeowners and businesses alike due to its durability, affordability, and aesthetic appeal. But have you ever wondered how this type of flooring is made? In this article, we will take you on a journey from tree to floor and explore the process of creating wood laminate flooring.

The first step in making wood laminate flooring is sourcing the raw material – wood. Most wood laminate flooring is made from high-density fiberboard (HDF) or medium-density fiberboard (MDF), which are engineered wood products. These products are made from wood fibers that are compressed and bonded together with resin. The wood fibers used in HDF and MDF are typically sourced from fast-growing trees such as pine, spruce, and eucalyptus.

Once the wood fibers have been sourced, they are then mixed with resin and other additives to create a thick, dense mixture. This mixture is then pressed and heated to form large sheets of HDF or MDF. These sheets are then cut into smaller planks, which will eventually become the individual pieces of laminate flooring.

The next step in the process is to create the design layer of the laminate flooring. This layer is what gives the flooring its realistic wood appearance. The design layer is created by printing a high-resolution image of wood grain onto a thin sheet of paper. This paper is then coated with a protective layer to prevent it from getting damaged during the manufacturing process.

Once the design layer is ready, it is time to assemble the laminate flooring. The HDF or MDF planks are first coated with a layer of adhesive, and then the design layer is placed on top. The planks are then pressed together under high pressure and heat, which fuses the layers together. This process is known as lamination, which is where the term “laminate flooring” comes from.

After the planks have been laminated, they are then cut into individual pieces and trimmed to the desired size. The edges of the planks are also treated with a special sealant to prevent moisture from seeping in. This is an important step as moisture can cause the planks to warp and damage the flooring.

The final step in the manufacturing process is to add a protective layer on top of the design layer. This layer is made from a clear, durable material such as aluminum oxide, which helps to protect the flooring from scratches, stains, and fading. This layer also gives the flooring its glossy finish.

Once the protective layer has been added, the planks are inspected for quality and then packaged for shipping. From here, the wood laminate flooring is ready to be installed in homes, offices, and other spaces.

In conclusion, wood laminate flooring is made through a complex process that involves sourcing raw materials, creating the design layer, laminating the planks, and adding a protective layer. This process results in a durable and affordable flooring option that mimics the look of real wood. So the next time you walk on your wood laminate flooring, you can appreciate the journey it took from tree to floor.

Behind the Scenes: The Manufacturing of Wood Laminate Flooring

Wood laminate flooring has become a popular choice for homeowners and businesses alike due to its durability, affordability, and aesthetic appeal. But have you ever wondered how this type of flooring is made? In this article, we will take a behind-the-scenes look at the manufacturing process of wood laminate flooring.

The first step in making wood laminate flooring is selecting the materials. The top layer, also known as the wear layer, is made of a high-quality photographic image of real wood. This image is printed onto a thin layer of paper and then coated with a protective layer of aluminum oxide. The core layer is made of high-density fiberboard (HDF) or medium-density fiberboard (MDF), which is a composite material made of wood fibers and resin. The bottom layer, also known as the backing layer, is made of melamine, a type of plastic that provides stability and moisture resistance.

Once the materials are selected, the manufacturing process begins with the preparation of the HDF or MDF core layer. The wood fibers are mixed with resin and then pressed together under high heat and pressure to create a dense and durable core. This process is similar to how plywood is made, but with a higher density and without the use of adhesives.

Next, the top layer is created by printing the photographic image of real wood onto a thin layer of paper. This image is created using high-resolution photography and advanced printing techniques to ensure a realistic and detailed design. The paper is then coated with a protective layer of aluminum oxide, which provides scratch and wear resistance.

The core layer and top layer are then bonded together using a high-pressure laminate (HPL) press. This press applies heat and pressure to fuse the layers together, creating a strong and durable bond. The backing layer is then added to the bottom of the core layer, completing the three-layer structure of wood laminate flooring.

After the layers are bonded together, the flooring goes through a cutting process. The laminate sheets are cut into planks or tiles of various sizes and shapes, depending on the desired design. The edges of the planks are then treated with a special sealant to prevent moisture from seeping in and causing damage.

Once the planks are cut and sealed, they go through a quality control process to ensure that they meet the industry standards. This includes checking for any defects, such as scratches or imperfections in the design. Any defective planks are discarded, and only the highest quality planks make it to the final stage of the manufacturing process.

The final step in the manufacturing process is the packaging and shipping of the wood laminate flooring. The planks are carefully stacked and packaged to prevent any damage during transportation. They are then shipped to retailers or directly to customers, ready to be installed in their homes or businesses.

In conclusion, the manufacturing process of wood laminate flooring involves selecting high-quality materials, pressing them together under high heat and pressure, and cutting and sealing them to create durable and aesthetically pleasing planks. This process ensures that wood laminate flooring is not only affordable but also durable and easy to maintain. So the next time you walk on your wood laminate flooring, you can appreciate the intricate process that went into making it.